Desoldering

If you soldered a wrong component to your PCB or you splilled some solder in wrong empty hole. You have several options to remove it without destroying your circiut.

De-soldering braid

To use the de-soldering braid place the braid on the unwanted solder joint.

Press your soldering iron onto the braid and wait until you see or feel the solder begin to melt and flow into the braid.

After the solder melts wait around two seconds and lift both the soldering iron and the braid. Gripping the braid’s holder, not the metal itself, as it will be hot.

Now, if everything went well, the braid should have absorbed the solder.

If some solder remains on the board, repeat the process.

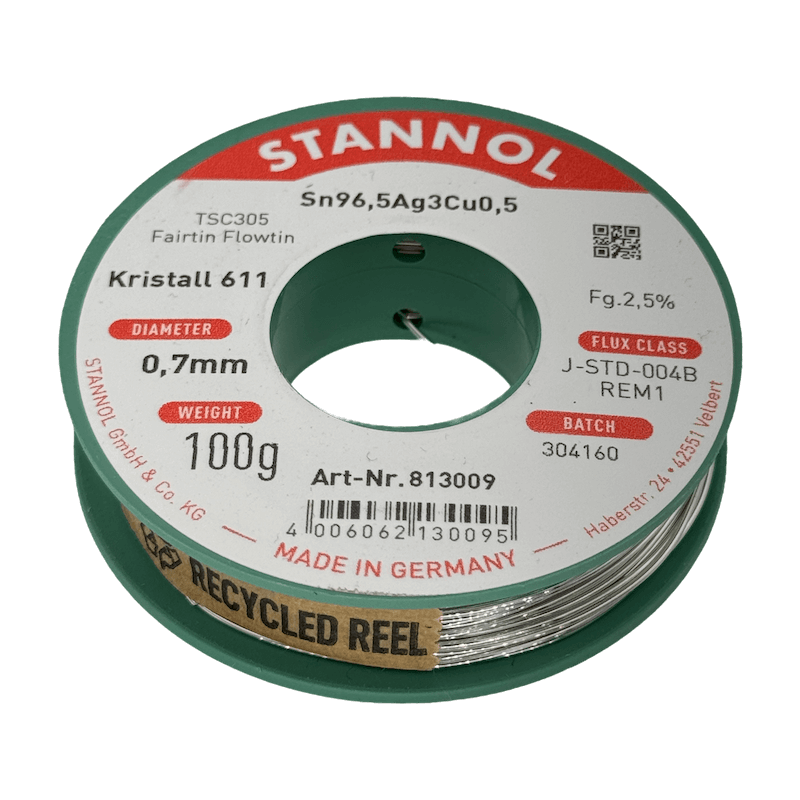

available

sold out at the moment

De-soldering pump

The de-soldering pump or solder sucker is a other tool to remove solder from your PCB.

Avoid using the pump near SMT (surface-mount) components, as the heat and suction can damage them.

Hold the pump firmly in your hand and push the plunger down until it

locks into place. Now the spring inside is compressed and the pump is

ready to go.

Heat the solder joint with your iron until the solder melts. A little fresh solder on the tip can help conduct heat better.

Place the pump nozzle as close as possible to the molten solder.

The tip is made of heat-resistant plastic, so it’s okay if it touches the soldering iron briefly.

Press the button on the side to release the pump. The pump snaps back,

creating a negative pressure at the tip. It’s a strong recoil, so brace

your hand and keep the pump steady.

Repeat as needed until the joint is clean. For any leftover residue, go back to using desoldering braid.

Desoldering

If you soldered a wrong component to your PCB or you splilled some solder in wrong empty hole. You have several options to remove it without destroying your circiut.

De-soldering braid

To use the de-soldering braid place the braid on the unwanted solder joint.

Press your soldering iron onto the braid and wait until you see or feel the solder begin to melt and flow into the braid.

After the solder melts wait around two seconds and lift both the soldering iron and the braid. Gripping the braid’s holder, not the metal itself, as it will be hot.

Now, if everything went well, the braid should have absorbed the solder.

If some solder remains on the board, repeat the process.

available

sold out at the moment

De-soldering pump

The de-soldering pump or solder sucker is a other tool to remove solder from your PCB.

Avoid using the pump near SMT (surface-mount) components, as the heat and suction can damage them.

Hold the pump firmly in your hand and push the plunger down until it

locks into place. Now the spring inside is compressed and the pump is

ready to go.

Heat the solder joint with your iron until the solder melts. A little fresh solder on the tip can help conduct heat better.

Place the pump nozzle as close as possible to the molten solder.

The tip is made of heat-resistant plastic, so it’s okay if it touches the soldering iron briefly.

Press the button on the side to release the pump. The pump snaps back,

creating a negative pressure at the tip. It’s a strong recoil, so brace

your hand and keep the pump steady.

Repeat as needed until the joint is clean. For any leftover residue, go back to using desoldering braid.

These guides are part of our effort to share practical knowledge about DIY synth building, tools, and Eurorack standards. We want them to be as clear and useful as possible, and we know there’s always room for improvement.

If you spot an error, think something could be explained better, or want to share your own DIY tips, please let us know. You can reach us at shop@exploding-shed.com or through our contact page .

These guides are part of our effort to share practical knowledge about DIY synth building, tools, and Eurorack standards. We want them to be as clear and useful as possible, and we know there’s always room for improvement.

If you spot an error, think something could be explained better, or want to share your own DIY tips, please let us know. You can reach us at shop@exploding-shed.com or through our contact page .